Key Takeaways

- Pipe fittings are crucial in connecting, controlling, and modifying the flow of liquids and gases.

- Understanding the types and materials of fittings helps ensure system efficiency and safety.

- Proper selection and installation are essential for preventing leaks and ensuring longevity.

Introduction to Pipe Fittings

Pipe fittings might go unnoticed in our daily lives, yet they play a fundamental role in ensuring the seamless operation of plumbing, gas, and HVAC systems. These small yet powerful components connect the pipework and regulate the flow of various substances, from water to complex chemicals.

Choosing the appropriate pipe fittings suppliers ensures that these components meet the necessary quality and specifications for your specific applications. A careful choice can enhance system robustness and reliability.

Beyond connecting pipes, fittings control flow direction and pressure. In diverse industries, ranging from residential plumbing to large-scale industrial processes, understanding these fittings’ basic types and functions is key to optimizing system efficiency and safety. As we delve into the types of pipe fittings, remember that selecting the right kind is essential to the longevity and success of the entire piping network.

Common Types of Pipe Fittings

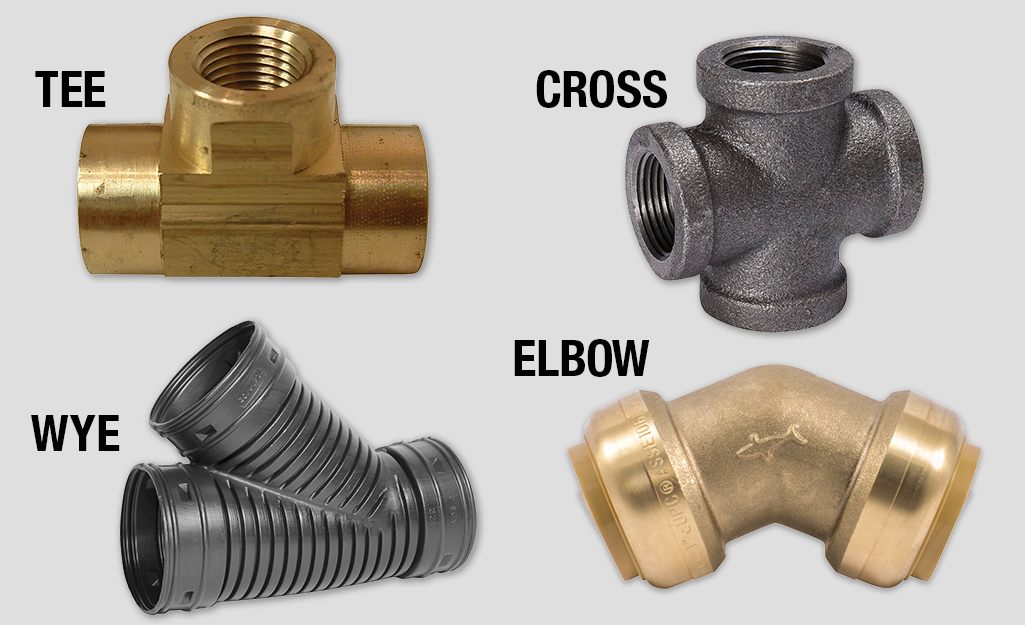

Pipe fittings come in various forms and types, each designed for specific functions. Common types include elbows, tees, couplings, unions, and reducers. Elbows change flow direction, while tees split the flow into two directions.

Couplings connect pipes of the same diameter, and unions allow easy disconnection for maintenance and repairs. Reducers adjust pipe diameter to control flow rate and pressure. Selecting the correct fitting for the job is imperative, as an incorrect fitting can lead to leaks, pressure loss, or system failure.

Importance of Material Selection

Material selection is crucial in the suitability and durability of pipe fittings. Various materials offer distinct properties, including durability, resistance to corrosion, and flexibility. Materials like stainless steel, copper, PVC, and PEX are widely used because of their advantages.

Stainless steel offers superior corrosion resistance and is great for harsh environments, while copper’s thermal conductivity is ideal for heating applications. PVC provides a cost-effective solution for non-metallic needs, and PEX offers flexibility and ease of installation.

Selecting the appropriate material reduces the risk of chemical reactions and material degradation, which enhances the fitting’s lifespan and reliability.

Installation Tips for Beginners

Proper installation of pipe fittings is just as vital as selecting the right type and material. Even the best fittings can fail if not installed correctly. Ensure all connections are clean and debris-free, and use the proper tools to avoid damage.

Applying sealants or thread tape can prevent leaks. Keep in mind that over-tightening can damage threads and lead to leaks. It’s always advisable to follow manufacturer guidelines and consider professional assistance if unsure.

Effective Maintenance Strategies

Regular maintenance is key to extending the life of your pipe fitting system. Routine checks for leaks, corrosion, and wear are essential. Replace any damaged fittings promptly to avoid system failure.

Maintenance should also ensure all connections remain tight and that any necessary lubricants or sealants are reapplied. Adhering to a proactive maintenance schedule can minimize downtime and expensive repairs, ensuring your pipe system operates at peak efficiency.