Printing has come a long way from the days of woodblocks and movable type. Today, advancements in materials play a crucial role in shaping modern printing technologies, enabling higher quality, greater efficiency, and more sustainable solutions. From flexible substrates to eco-friendly inks, innovations in materials are driving the industry forward in ways that were unimaginable just a few decades ago.

The Rise of Eco-Friendly Printing

One of the most significant changes in the industry is the shift towards sustainable materials. Traditional printing often relied on materials that were not environmentally friendly, but today, there is a strong push for biodegradable, recyclable, and non-toxic options. Water-based inks, soy-based alternatives, and PVC-free substrates are now more widely available, reducing the environmental impact of large-scale printing. These advancements not only help businesses meet sustainability targets but also appeal to eco-conscious consumers.

High-Performance Substrates for Every Application

Innovations in printing materials have led to the development of specialized substrates tailored to different applications. High-performance fabrics, vinyl, and synthetic papers now offer enhanced durability and versatility. Modern substrates ensure long-lasting and vibrant results, whether for outdoor banners, vehicle wraps, or fine art reproductions. Materials engineered to be weather-resistant, UV-stable, and tear-proof have expanded the possibilities of large-format and digital printing.

Smart and Functional Printing Materials

Beyond aesthetics, new materials in printing now offer functional benefits. Conductive inks allow for the creation of printed electronics, such as flexible circuits and interactive packaging. Thermochromic and photochromic inks enable color changes based on temperature or light exposure, enhancing security printing and novelty applications. Additionally, antimicrobial coatings are increasingly used in medical and food-safe packaging, offering added hygiene protection.

Digital Printing and Material Compatibility

The rise of digital printing has further increased the demand for innovative materials. Unlike traditional offset printing, digital printing requires substrates to handle fast ink absorption and high-resolution output. Coated papers, textiles, and synthetic films designed specifically for digital presses help ensure sharp images, accurate colors, and consistent quality. The versatility of these materials allows for personalized and short-run prints that were previously challenging to produce cost-effectively.

The Role of Suppliers in Advancing Printing Materials

Suppliers play a key role in providing solutions that meet industry needs as the demand for advanced printing materials grows. Companies like Soyang offer diverse high-quality printable materials, including eco-friendly options and cutting-edge substrates for large-format printing. Go to the Soyang website to find out more. By working with innovative suppliers, businesses can stay ahead of trends and access the latest advancements in printing technology.

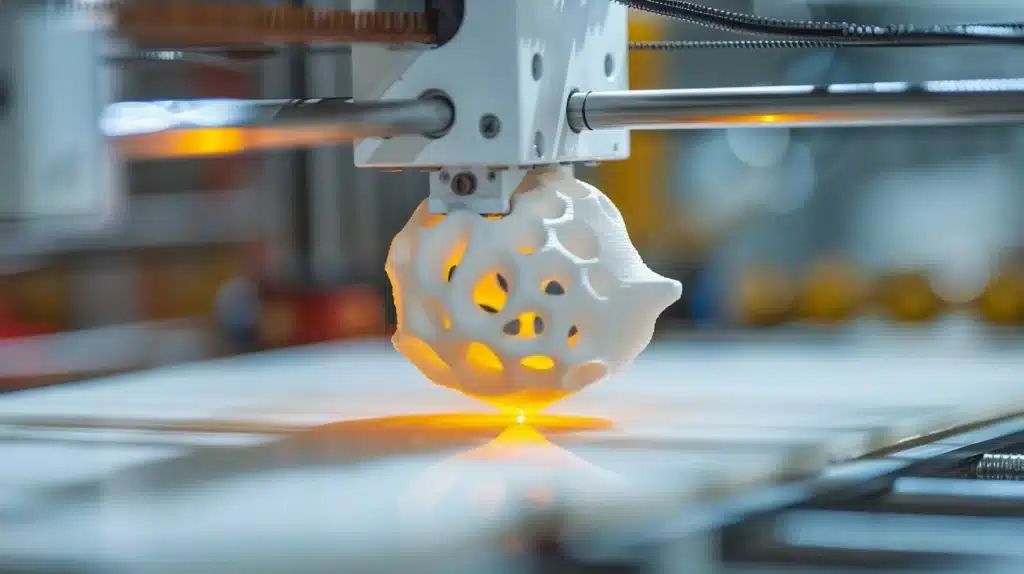

The Future of Printing Materials

The industry is expected to see even more breakthroughs in printing materials. Nanotechnology, bio-based inks, and fully recyclable substrates will continue to shape the future of printing. As businesses and consumers place greater emphasis on sustainability, efficiency, and performance, material innovation will remain a driving force in the evolution of modern printing.

From sustainable solutions to high-tech applications, advancements in printing materials are redefining what is possible. As technology progresses, the synergy between new materials and printing techniques will continue to open up exciting opportunities across various industries.